In a new study, recently published in Nature Electronics, the researchers took inspiration from spider silk, which can adapt and adhere to a number of surfaces, to formulate the method.

These silks also incorporate bioelectronics, so that different detection capabilities can be added to the “web”.

The discovery opens the door to the development of a new type of biometric sensor, less intrusive than those currently used, for example, in smartwatches.

According to Ciencia Plus, the fibers are at least 50 times smaller than a human hair, and so light that the researchers printed them directly onto the head of a dandelion without collapsing its structure.

“If we want to accurately sense anything on a biological surface such as skin or a leaf, the interface between the device and the surface is essential,” says study leader Yan Huang in a statement.

“We also want bioelectronics to be completely imperceptible to the user, so that it doesn't interfere in any way with the way they interact with the world, and we want it to be sustainable and low-waste,” adds Huang.

3D printing is also another potential avenue for bioelectronics, since it produces less waste than other production methods, but forms thicker devices that can interfere with normal behavior.

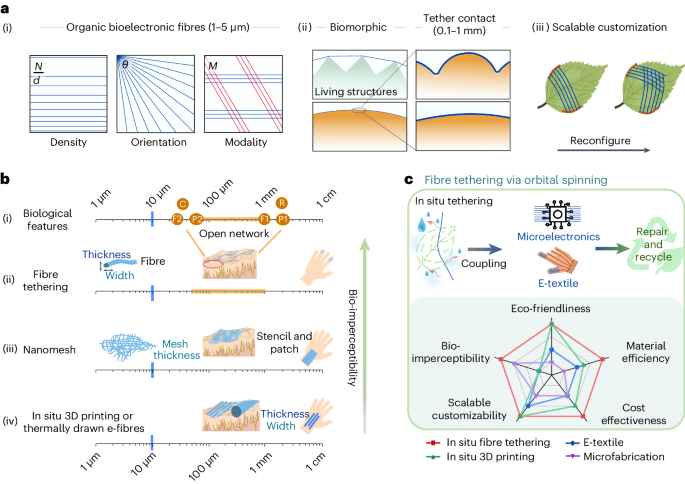

In the study, the team developed a new way to create high-performance bioelectronics products that can be customized for a wide range of biological surfaces, from the tip of a finger to the head of a dandelion, by printing directly onto that surface.

The researchers created their bioelectronic “spider silk” from PEDOT:PSS - a biocompatible conductive polymer, hyaluronic acid and polyethylene oxide.

The high-performance fibers were produced from a water-based solution at room temperature, which allowed the researchers to control the “spinability” of the fibers.

The researchers developed an orbital spinning approach to allow the fibers to transform into living surfaces, even microstructures like fingerprints.

Tests of the bioelectronic fibers, on surfaces including human fingers and dandelion heads, showed that they provided high-quality sensor performance while being imperceptible to the host.

“Our spinning approach allows bioelectronic fibers to follow the anatomy in different ways, both at the micro and macro scale, without the need for any image recognition,” said first author of the study Wenyu Wang.

“This opens up a whole new angle in terms of how sustainable electronics and sensors can be manufactured. It's a much easier way to produce large-area sensors,” Wang concludes.

The researchers say the devices could be used in applications ranging from health monitoring and virtual reality to precision agriculture and environmental monitoring.

In the future, other functional materials could be incorporated into this fiber printing method to build integrated fiber sensors to augment computing and energy conversion systems.